Manufacturing technologies/facilities

Kakusan Food Co., Ltd. works at accumulating manufacturing techniques and know-how at all times to meet the needs of all customers.

We actively invest in our facilities, aspiring to enhance product quality and production efficiency.

Main facilities

Blending pot

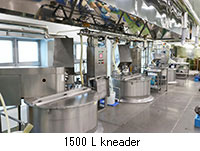

Blending potWe have a lineup of pots of various capacities, ranging from 150 L to 1500 L, to blend, heat and cool raw materials. We use different pots depending on the purpose and quantity of manufacturing. As for the clinoaxis kneader with its strong agitation power, we have one unit of 800 L and five units of 1500 L to manufacture products of uniform and stable quality. |

Automatic filling machine

Automatic filling machineThe machine is able to fill the precise amount at high temperature. After the filling, it can also tighten the cap automatically. |

Automatic filling machine(PET bottle, No.4 can)

Automatic filling machine(PET bottle, No.4 can) This machine fills a fixed amount of products into PET bottles and No.4 can. It fills precise amount of products at high temperature under a hygienic condition. The machine can fill PET containers of 500 ml, 1.0 L, and 1.8 L, as well as No.4 can. |

Cooling machine for 18 L cans

Cooling machine for 18 L cansProducts that have been filled at high temperature need to be cooled down quickly. This machine cools down 18 L cans after filling them at over 90°C to below 40°C within five minutes to maintain the product quality. |

Desalination machine Desalination machineAnalyze the salt content by computer, and desalinate the fish extracts, etc. to the targeted salinity. |

Plate-type sterilization machine Plate-type sterilization machineMaintain the quality of products by quickly pasteurizing heat-tolerant bacteria, such as spore forming bacteria, at 130°C and by cooling. |

Membrane separation device

Membrane separation deviceSeparate high and low molecular components using a membrane. |

Flash-type vacuum concentration machine

Flash-type vacuum concentration machineWe concentrate extracts in a low-temperature, low-pressure environment. We can also concentrate foamable extracts effectively to maintain the quality of their flavor. |

Small spray drier Small spray drierWe manufacture small amounts of extract powder samples, mainly seafood extracts. |

High-speed filling machine for small bags

High-speed filling machine for small bagsUsing six high-speed filling machines, we can fill a wide variety of sizes, ranging from 20g to 500g. Immediately after filling at high temperature, it is cooled with water to maintain quality. We have received many requests for OEM manufacturing. |

Heating cooling homogenizer Heating cooling homogenizerOne-batch processing of dispersion, emulsification, stirring, and cooling under atmospheric pressure and vacuum can be performed. 1,500L Heating cooling homogenizer Σ |

Filter press Filter pressFilter press machine |

Robot palletizerThis system uses a robot to hold 18L cans by suction cups and stack them on pallets.Cans can be stacked as accurately and seamlessly as if they were stacked by human hand. |